We purpose to bring a few improve in modern day scholarly communications through the productive utilization of editorial and publishing polices. Examine Much more Authors’ Constitution

This cookies is about by Google Common Analytics to throttle the request fee to limit the collection of information on high traffic internet sites.

The CEDI method works by using a combination of mixed resin, selectively permeable membranes, and an electric charge, supplying steady stream (item and waste focus) and steady regeneration. Water enters both equally the resin part as well as the waste (concentrate) portion. Mainly because it passes through the resin, it is actually deionized to be merchandise water. The resin acts for a conductor enabling the electrical probable to drive the captured cations and anions from the resin and acceptable membranes for concentration and elimination inside the squander water stream.

The validation program need to be made to ascertain the suitability of the process and to offer an intensive knowledge of the purification system, variety of functioning conditions, needed pretreatment, as well as the almost certainly modes of failure. It is usually required to demonstrate the success on the checking scheme and to determine the documentation and qualification requirements for your system's validation servicing. Trials performed in the pilot installation is usually important in defining the operating parameters and also the envisioned water top quality and in determining failure modes. However, qualification of the particular unit Procedure can only be performed as Element of the validation in the put in operational program. The choice of certain unit operations and structure attributes to get a water program ought to consider the quality of the feed water, the technologies preferred for subsequent processing techniques, the extent and complexity of the water distribution process, and the appropriate compendial necessities. One example is, in the look of a technique for Water for Injection, the final process (distillation or whatever other validated procedure is used according to the monograph) needs to have productive bacterial endotoxin reduction capacity and have to be validated.

Put together sample by dissolving 10g of merchandise less than test in 100 ml of Soybean Casein digest medium.

In this action, the entire amount of aerobic organisms is decided, here which is a crucial indicator to measure the hygienic quality of medicines.

For drug commodities, equally safety and performance are essential. Within the a single hand, drug basic safety is decided by if the chemical composition and material with the drug are Protected, and On the flip side, drug basic safety is set by whether or not the drug is contaminated by microorganisms. There are plenty of forms of microorganisms. Following contaminating prescription drugs, They could decompose the powerful ingredients of medication, leading to decreased or missing efficacy.

Pretty much, most bioburden dies off in the course of true manufacture of your pill. It is because of The huge dust generated all through manufacture (operators wear individual protective machines, together with respirators), temperature inside the manufacturing places and as mentioned, lack of water essential for advancement and also the poisonous composition of a lot of the excipients and Energetic pharmaceutical agents applied to provide stable oral dosage formulations.

If a greater amount of replicates is required during the validation review, the comparisons may be evaluated by transforming the figures of cfu for their logarithmic values and examining the data statistically by the scholar t test (pairwise comparisons) or by analysis of variance (ANOVA) (for evaluating all groups).

This validation testing is named the MLT Process Suitability Test. If these antimicrobial Attributes are present, these could be removed by dilution, filtration, neutralization or inactivation ahead of testing the item.

This cookie is ready by Litespeed Server and permits the server to retail store options that can help boost performance of the positioning.

The inoculum is specifically plated onto the solid medium. It is achievable that filtration will lead to lowered Restoration from the obstacle microorganism, both by way of inherent toxicity of your membrane or by adherence on the microrganism for the filtration vessel walls. A Management team can be utilized To guage this element of membrane filtration validation.

as creating no appreciably interfering gas chromatography peaks. Referenced monographs specify working with this water as the solvent for standard and test Resolution preparing for the Natural unstable impurities test Direct-No cost Water— This water is utilized as being a transferring diluent for an analyte inside of a Lead

The test has not altered basically with regard to execution considering the fact that its inception. In a single sense it may be argued that engineering from the last century is being used to launch product or service designed while in the 21st microbial limit test sop century, and therefore serve as a microbiological Command for launch of product for human use. The MLT is created to present quantitative facts with regard to numbers and qualitative information and facts of feasible organisms existing in samples. Depending upon the media applied complete aerobic microbial counts, full yeast and mold counts in addition to a qualitative analysis for E. coli

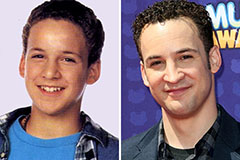

Ben Savage Then & Now!

Ben Savage Then & Now! Brandy Then & Now!

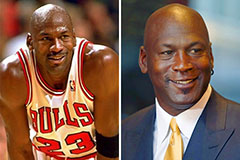

Brandy Then & Now! Michael Jordan Then & Now!

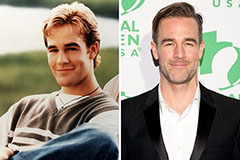

Michael Jordan Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now!